Island Stories:

![]() Danzig

Mine

Danzig

Mine

![]() Zeballos

Iron Mine

Zeballos

Iron Mine

![]() Conuma

Peak 1910

Conuma

Peak 1910

Alexandra Peak

Argus Mountain

Bate/Alava Sanctuary

Beaufort Range

Big Interior Mtn

Big Interior Mtn 1913

Part 1

Part 2

Bolton Expedition 1896

Cliffe Glacier

Clinton Wood

Comox Glacier

Comox Glacier 1922

Comox Glacier 1925

Comstock Mtn

Conuma Peak

Copper King Mine

Crown Mtn

Elkhorn 1912

Elkhorn 1949

Elkhorn 1968

Eugene Croteau

Golden Bullets

Golden Hinde 1913/14

Golden Hinde 1937

Golden Hinde 1983

Harry Winstone Tragedy

Jack Mitchell

Jim Mitchell Tragedy

John Buttle

Judges Route

Koksilah's Silver Mine

Landslide Lake

Mackenzie Range

Malaspina Peak

Mariner Mtn

Marjories Load

Matchlee Mountain

Mount McQuillan

Mt. Albert Edward

Mt. Albert Edward 1927

Mt. Albert Edward 1938

Mt. Becher

Mt. Benson 1913

Mt. Benson

Mt. Doogie Dowler

Mt. Colonel Foster

Mt. Hayes/Thistle Claim

Mt. Maxwell

Mt. Sicker

Mt. Tzouhalem

Mt. Whymper

Muqin/Brooks Peninsula

Nine Peaks

Queneesh

Ralph Rosseau 1947

Rosseau Chalet

Ralph Rosseau Tragedy

Rambler Peak

Red Pillar

Rex Gibson Tragedy

Sid's Cabin

Steamboat Mtn

Strathcona Park 1980's

The Misthorns

The Unwild Side

Victoria Peak

Waterloo Mountain 1865

Wheaton Hut/Marble Meadows

William DeVoe

Woss Lake

You Creek Mine

Zeballos Peak

Other Stories:

Sierra

de los Tuxtlas

Antarctica

Cerro del Tepozteco

Citlaltepetl

Huascaran

Mt. Roraima

Nevada Alpamayo

Nevada del Tolima

Nevado de Toluca

Pico Bolivar

Popocatepetl

Uluru/Ayers Rock

Volcan Purace

Volcan San Jose

Zeballos Iron Mine

by Lindsay Elms

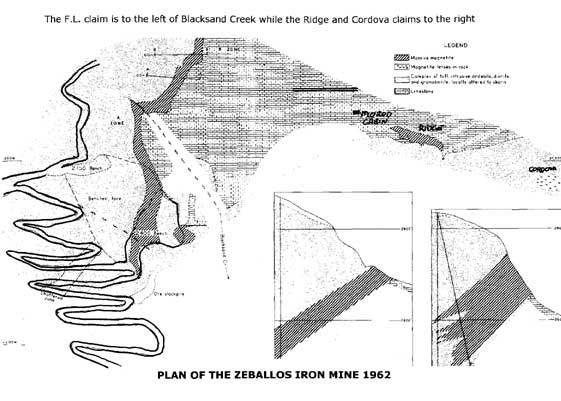

From a gated road between Pandora Creek and Blacksand Creek about 4-5 kilometres before reaching Zeballos, an old undriveable switch-back road zig-zags up the spur for 5 kilometres to the site of the Zeballos Iron Mine which operated in the 1960's. There are three main crown grants where the magnetite is found: F.L., Ridge and Cordova, the last two being on the north side of Blacksand Creek; however, it was the F.L. grant where the majority of both the above-ground and below-ground mining took place. I am currently unaware of who initially staked the F.L. claim, but Andy Morod, a Swiss immigrant who became well-known as an explorer/prospector in the Zeballos area, had staked some claims on the Ridge site prior to the 1950's and built a cabin nearby. He accessed the area by a trail he had to build.

|

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1950:

A detailed geological examination and dip-needle survey were carried out in 1951 and twelve holes were diamond drilled to aid in outlining the impressive surface showings of magnetite. In 1952 nine holes were drilled. The principal showings on Blacksand Creek are reached by a pack-horse trail from a road along the west bank of the Zeballos River. It consists of five Crown-granted and two recorded mineral claims leased from the Ford Iron Syndicate; five Crown-granted claims on which Anyox Metals Limited holds all rights in iron ore by agreement with Andy Morod, R.V. Murphy, and others; and one claim held by record by Anvox Metals Limited.

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1960:

In 1959 and 1960 an additional nineteen diamond-drill holes were drilled. Since June, 1960, the construction of a truck-road from the Zeballos River road to the main magnetite outcrop at an elevation of 2,500 feet was almost completed and a right-of-way was cleared for an inclined surface tram extending from the main outcrop to the mill-site near the river.

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1961:

F.L. Mines Limited (Zeballos Iron mine) owns seven recorded claims and holds thirteen Crown-granted claims under lease from Ventures Limited and eighteen recorded claims under option from various owners, on the west side of Zeballos River. The claims extend from the river mouth to a point 3 miles upstream to Blacksand Creek, astride which is an occurrence of magnetite. In 1961 the number of men employed varied between twenty and 225, depending upon the amount of construction work being done. The construction of the crushing plant, surface tramline, beneliciating plant, tailings disposal, and shiploading facilities was 80 per cent completed at the end of the year. The designed daily capacity of the plant is 3,600 tons of mill feed. Surface stripping of the planned pit area began in December, and 23,000 cubic yards of overburden was drilled and blasted during that month.

From The Minister of Mines and Petroleum Resources. Annual report ending December 31, 1962:

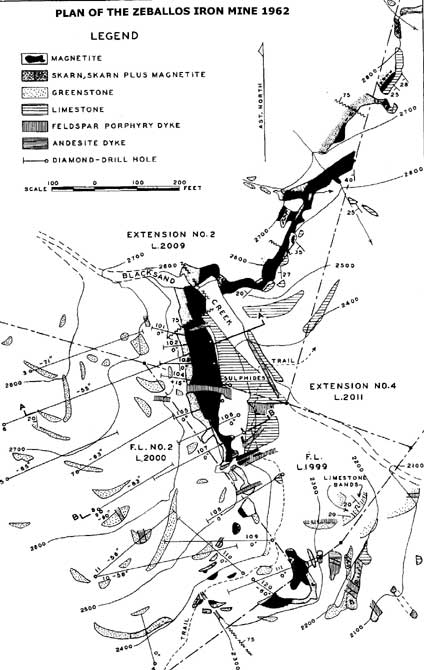

The F.L. deposit is covered by the F.L., F.L. No. 2, F.L. No. 3, F.L. No. 4, Extension No. 2, and Extension No. 4 Crown-granted mineral claims. The Ridge deposit is covered by the Extension No. 4 and by the Ridge Fraction recorded claim. The F.L. and Extension claims are owned by Falconbridge Nickel Mines Limited, and Zeballos Iron Mines Limited was mining the F.L. deposit under royalty agreement. In 1962 Zeballos Iron Mines optioned the Churchill group of recorded claims from S. N. Ray and J. W. Foster, the Ridge Fraction from Andy Morod, of Zeballos, and the Cordova and Treena recorded claims from H. Sutton, of Zeballos. The Churchill and Cordova-Treena options were dropped. The F.L., Ridge, and Cordova magnetite deposits are on the steep north slope of the Zeballos River valley, and the Churchill lies 2 miles to the north, on the dividing ridge between the Zeballos and Kaouk Rivers.

The F.L. lies between 2,350 and 2,900 feet elevation, diagonally crossing the canyon of Blacksand Creek, a tributary of the Zeballos River. The Ridge deposit is on the upper west slope of the ridge between Blacksand and Lime Creeks. The Cordova magnetite showings are on the upper Lime Creek slope, a short distance east of the Ridge. For practical purposes the F.L. orebody is divided into an A zone south of Blacksand canyon and a B zone north of it. An open pit has been established on the A zone, with the main bench at about 2,400 feet elevation. The F.L. open pit is reached by 5 miles of road from Zeballos to the mill and office at 400 feet elevation on the north side of the Zeballos River, and by 3 miles of steep switchback road up the ridge between Pandora and Blacksand Creeks. An extension of this road crosses Blacksand Creek above the canyon and provides access to diamond sites on the B zone. A foot-trail crosses the canyon at the 2,400- foot bench and leads to the Ridge deposit. The Cordova showings may be reached by foot-trail up Lime Creek, but are now more easily reached by descending from the Ridge.

Ore from the open pit is trucked down to the crusher at 2,100 feet elevation. From the crusher it is carried by surface tram down the ridge between Pandora and Blacksand Creeks to a stockpile at about 800 feet elevation. From the stockpile it is carried by belt conveyor to the mill, where it is split into three sizes. The two coarser sizes pass over dry magnetic separators, the finest over a wet separator. The three concentrates are combined into a lump concentrate between one-quarter and 3 inches and conveyed by belt to a stockpile. From the stockpile the concentrate is hauled in Kenworth tandem trucks to the deep-sea loading-dock in Zeballos.

Ore and waste rock were mined concurrently. The A zone dips west at about 45 degrees into the wall of Blacksand Creek canyon, and a large volume of waste rock has to be removed from the hangingwall. Ore was mined solely from the main, 2400 level, bench. Several subsidiary benches were established between 2,470 and 2,750 feet elevation to facilitate waste removal. In part the waste was bulldozed directly into the canyon over the north end of the A zone; in part it had to be bull-dozed onto the 2400 level bench and loaded into trucks for dumping over the outer edge of the bench. A total of 369,289 tons of ore and 687,000 cubic yards of waste was mined. The mill started up in April, and produced 250,397 tons of concentrate in 1962. The first ore ship loaded late in May. On the average, 115 men were employed, and were accommodated in Zeballos.

Briefly, the deposits occur along the contact zone between Quatsino limestone and the Zeballos batholith, where the limestone bulges southwest into the intrusive. In this part of the area the batholith is not a homogeneous body, but rather a complex of diorite and variably recrystallized Bonanza pyroclastics that is further intruded by dykes, stockworks, and irregular small stocks of light-coloured quartz diorite and granodiorite. Toward the south end of the F.L. deposit, at the south corner of the bulge, the limestone is in contact with this complex, but to the north and east it is separated from the complex by a continuous sheath of Bonanza pyroclastics. Hoadley termed the bulge a lobate roof pendant preserved on a cross anticline plunging southwest down the dip of the regional structure.

The main F.L. orebody is a nearly planar dyke-like body of nearly massive magnetite which in part appears to follow the Quatsino-Bonanza contact on the nose and northwest limb of the bulge. It dips about 45 degrees west and strikes due north in the A zone and north-northeast in most of the B zone. Adjacent to Blacksand Creek structure contours on the hangingwall swing to a northwest strike, reflecting drag on a fault in the creek that has offset the orebody to the right. The A and the south part of the B zone are about 100 feet thick; northward the body tapers to a pinchout.

The Ridge deposit is a small rectangular plate of almost pure magnetite lying on limestone close to its east-trending contact with Bonanza tuffs. It is 300 feet long and 50 feet wide; diamond drilling has shown it to be shallow, so that it is estimated at 50,000 tons. The only impurities are a few scattered inclusions of limestone and feldspar porphyry. Skam is extremely rare in the magnetite, in the limestone, and also in feldspar porphyry dykes and a body of intrusive andesite along the west part of the north contact of the magnetite. The tuffs do contain considerable pyroxene, which may be regarded as a skarn mineral, but they contain very little epidote and garnet. This pyroxene continues in tuffs near the limestone contact over the crest of the ridge and down the Lime Creek slope onto the Cordova claim.

The Cordova magnetite showing is on the steep west slope of Lime Creek between 2,200 and 2,300 feet elevation, It consists of small lenses of massive magnetite in heavily pyroxenized tuffs, some 200 feet south of the limestone contact and just north of and below a small quartz diorite intrusion.

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1963.

The present company commenced work on the property in 1959. Open-pit mining was begun in 1962, and by the end of that year 250,397 tons of iron concentrate had been shipped. On February 27, 1963, the property was closed down. After a complete reorganization of the company and change of control, the property was reopened on November 1st. It is now intended to abandon the open-pit operations and prepare for underground mining. Approximately 70,000 cubic yards of waste was stripped during the year, and 13 holes were diamond drilled, totaling 2,095 feet. A new bunk-house camp was being constructed at the end of 1963 to accommodate 60 men. A crew of 80 men was employed at the beginning of the year and about 15 men after reopening in November.

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1964.

After a complete reorganization of the company and change of control, the property was reopened on November 1, 1963, and prepared for renewed production as an underground mine. All underground development work and production was carried out under contract. A main-haulage adit level was established at 2,280 feet elevation, and subsequently two further adit levels were driven at 2,375 and 2,440 feet elevations respectively. The system of mining is longhole blasting with mucking-machine draw points.

A limited amount of open-pit mining was done near the main-adit portal. The first production under the reorganized company was in July. Total production of iron concentrates in 1964 was 92,727 tons.

The ore is trucked from the mine to the primary crusher at 2,100 feet elevation. It then passes through a secondary crusher and into a 100-ton surge bin. From there it is drawn in 9-ton steel skips which descend over standard-gauge triple track surface tram to the crude-ore stockpile just above the mill. The surface tram-line is 2,500 feet long and extends from elevation 1,900 feet to the mill horizon of 1,200 feet. At the mill the ore is beneficiated by magnetic separation. It is then trucked to a loading dock at the head of Zeballos Inlet, where a stacker conveyor delivers the ore to a stockpile which may contain up to 80,000 tons. An underground conveyor system removes ore from the stockpile and loads directly into the holds of ocean-going freighters. A total crew of 9 men was employed, 52 being employed underground.

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1965.

In 1965 the three stopes in the "A" zone were mined, and development work was carried out in the "B" zone, to the north of "A" zone. A number of improvements were made to the mine camp. A compressor-house was erected, a community hall, first-aid, and mine-rescue building was completed for use in July, and at the end of the year arrangements for man-haulage on the surface tram were completed. A total crew of 106 men was employed, 43 being employed underground. Total production of ore trammed to the mill was 364,115 tons. Total iron concentrates produced in 1965 was 267,823 tons.

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1966.

In 1966 the stopes in "A" zone were mined out, leaving only the ribs and crown pillars. Development work was completed in the "B" zone, to the north of "A"zone, and two stopes in this zone were brought into production. A total crew of 100 men was employed, 45 being employed underground. Total production of ore trammed from the mill was 365,576 tons. Total iron concentrates produced was 323,302 tons.

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1967.

In 1967 the development work in "B" zone was completed, and the two stopes in this zone were mined. By the end of the year the long-hole blasting in the stopes had broken through to the surface. The ore from these stopes is loaded out at drawpoints on "B" level at 2,440 feet elevation and put through an ore-pass to the main haulage at 2,280 feet elevation. Total production of ore milled was 372,198 tons. Total iron concentrate produced was 256,806 tons.

From the Minister of Mines and Petroleum Resources Annual report ending December 31, 1968:

All development was completed by the autumn of 1967. In 1968 the three pillars between the stopes in "A" zone were mined. No. 2 pillar was blasted in February, No. 3 pillar in May, and No. 1 pillar in August. The loading out of broken ore was still in progress by year end but it is expected that the operation will be completed in early 1969.

The powerhouse was burned to the ground on May 4 and all machinery destroyed. The origin of the fire is unknown. A new temporary power plant was built to operate the mill until the mine is worked out, which probably will be in early 1969.

After 1968

the mine never operated again and nature has began to reclaim the land.

The switch-back road that winds up to the mine site is overgrown with

alder; however, the hangingwall where the underground mining took place

is an amazing site.

|

|

|

|

|

|

|

|

How to order | | About the Author || Links || Home

Contact:

Copyright ©

Lindsay Elms 2001. All Rights Reserved.

URL: http://www.beyondnootka.com

http://www.lindsayelms.ca